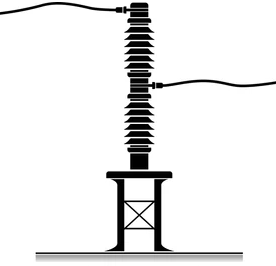

What is Transformer Bushing?

An insulating device called a transformer bushing makes it easier for an energised conductor to pass through the grounded tank of a transformer. The transformer windings are connected to the external electrical system using bushings, which need to be able to handle high voltage and current without failing.

Transformer bushings come in two primary categories: low-voltage bushings and high-voltage bushings. For voltages under 15 kV, low-voltage bushings are utilised, whereas high-voltage bushings are used for voltages over 15 kV.

Porcelain or epoxy are frequently used to make low-voltage bushings. Porcelain bushings are more expensive but also more robust and can withstand greater volts. While less expensive, epoxy bushings are less robust and can only withstand lower voltages.

Typically, silicone rubber or oil-impregnated paper are used to make high-voltage bushings. Oil-impregnated paper bushings are more expensive but also more enduring and capable of withstanding higher voltages. While cheaper, silicone rubber bushings are less reliable and can only withstand lower voltages.

The design of a transformer bushing must take into account the following factors:

- The voltage and current rating of the bushing

- The environmental conditions at the transformer location

- The cost of the bushing

The bushing needs to be capable of withstanding the highest possible voltage and current that it will encounter while in use. The bushing must be able to survive the temperature, humidity, and pollution that are present at the location of the transformer. Consideration should also be given to the bushing's price, which can range from a few hundred to several thousand dollars.

The bushing is made once the final design has been determined. Depending on the bushing type, several steps are involved in manufacture, but generally speaking they go like this:

- The bushing is moulded to create it.

- The bushing has an insulating substance applied to it.

- Bushing is healed.

- To make sure the bushing satisfies the necessary requirements, it is tested.

The transformer tank receives the bushing once it has been built. Usually, the bushing is screwed into the tank's threaded hole. The transformer windings are next connected to the bushing.

Transformer bushings are an essential component. They enable the transformer to remain functional while being connected to the external electrical system. Transformers must operate safely and reliably, which requires correct bushing design, production, and installation.

Here are some additional details about transformer bushings:

- Bushings are often composed of epoxy or premium porcelain.

- In bushings, the insulating material's central metal conductor flows through the substance.

- A certain voltage and current are the ratings for bushings.

- To avoid electrical shock, bushings must be properly grounded.

- Bushings need to be frequently inspected for signs of damage.

- Damaged bushings need to be replaced right away.

The grid's transformer bushings are a crucial component. They make it possible for transformers to connect to the external electrical system securely and dependably. In order to guarantee the safe and dependable operation of the electrical grid, bushings must be properly designed, produced, installed, and maintained. Know more at www.yashhv.com

.png)

.jpg)

Comments

Post a Comment